Contrary to popular belief, your “natural” fabrics may be the source of skin irritation due to a hidden ecosystem of processing chemicals and bacteria.

- Conventional cotton is laden with pesticides, while “eco-friendly” bamboo viscose is produced with harsh, toxic solvents.

- True skin relief comes from choosing fabrics certified for chemical purity, like GOTS cotton, or those with inherent antimicrobial properties, like wool and linen.

Recommendation: Audit your wardrobe not just for fiber type, but for certification. Prioritize GOTS-certified textiles to create a pure, non-irritating barrier for your skin.

That persistent, unexplained rash or intermittent eczema flare-up can be a source of immense frustration. You’ve switched to a hypoallergenic laundry detergent, ruled out food allergies, and meticulously moisturized, yet the irritation lingers. The conventional wisdom points you toward “natural fibers,” suggesting that a simple switch to cotton should solve the problem. However, this advice often overlooks a crucial, microscopic truth: the fabric itself is an environment, one that can be either a serene sanctuary or a toxic habitat for your skin.

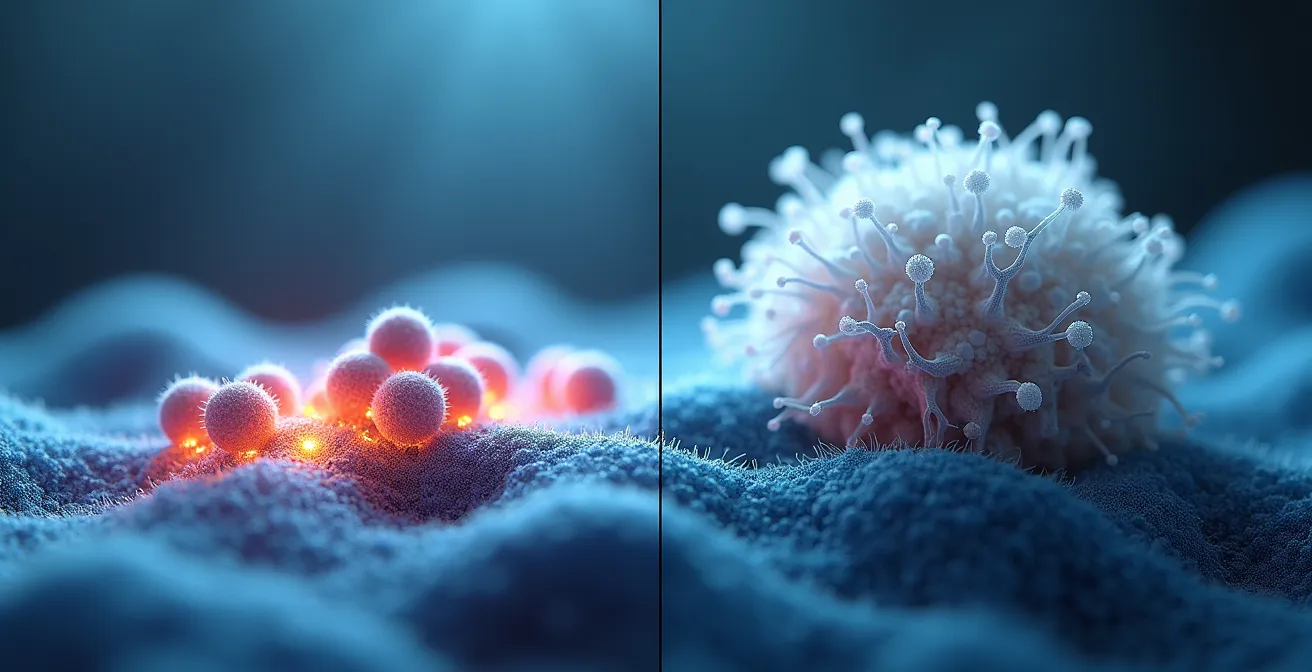

From a toxicological standpoint, the problem isn’t necessarily the cotton fiber itself, but the invisible burden it carries from the field to your closet. This includes a complex cocktail of agricultural pesticides, industrial processing agents, and even the microbial life that synthetic fabrics encourage. The assumption that “natural” equals “pure” is a dangerous oversimplification. The real key to resolving these mysterious skin issues lies not in simply choosing a natural fiber, but in demanding absolute chemical purity and understanding how a fabric’s very structure interacts with your body’s microbiome.

This article will deconstruct the common myths surrounding textiles and skin health. We will move beyond the surface-level debate of natural versus synthetic to explore the scientific reasons why certain fabrics irritate while others soothe. We will analyze the hidden dangers in conventional cotton and bamboo, uncover the unique benefits of linen and hemp, and provide a clear, science-backed framework for building a wardrobe that actively promotes skin health, offering you the relief you’ve been searching for.

To guide you through this complex world of textile science, this guide breaks down the critical factors you need to understand. From the agricultural realities of cotton production to the molecular reasons why polyester harbors odor, we will equip you with the knowledge to make truly informed choices for your health and comfort.

Summary: Why Switching to GOTS-Certified Cotton Can Resolve Unexplained Skin Rashes?

- Why “Natural” Cotton Still Contains Pesticides After Washing?

- Hemp vs Cotton: Which Plant Uses Less Water per T-Shirt?

- The Bamboo Fabric Lie: Why “Bamboo Viscose” Is Actually Toxic to Produce?

- The “Break-In” Period That Makes Linen Softer Than Cotton Over Time

- When to Buy Organic Linens to Get the Best White Sale Discounts?

- The Hidden VOCs in Modern Furniture That Affect Your Sleep Quality

- Why Polyester Wicks Sweat but Smells Worse Than Wool?

- How to Build a Capsule Wardrobe That Lasts 5 Years Without Looking Dated?

Why “Natural” Cotton Still Contains Pesticides After Washing?

The term “natural” applied to conventional cotton is misleading from a chemical purity perspective. The journey of this fiber begins in fields where intensive chemical agriculture is the norm. In fact, a staggering 96% of US cotton is genetically modified, often to withstand herbicides like glyphosate. In 2021 alone, US cotton farming utilized 700 million pounds of synthetic nitrogen fertilizer. These substances are designed to be persistent, and their residues can embed within the plant’s cellular structure, making them difficult to remove entirely through standard washing and processing.

While industrial scouring removes many surface chemicals, it doesn’t guarantee the elimination of all systemic pesticides absorbed by the plant during its growth. For individuals with sensitive skin, eczema, or Multiple Chemical Sensitivity (MCS), even trace amounts of these agricultural chemicals can be enough to trigger an inflammatory response, leading to rashes and irritation that seem to have no obvious cause. This is where the Global Organic Textile Standard (GOTS) becomes critically important.

GOTS certification is not just an “organic” label; it’s a guarantee of purity throughout the entire supply chain. A key update in GOTS 7.0, implemented in the 2024 ginning season, mandates that all cotton must be sampled and tested for both GMOs and pesticide residue before it even undergoes its first processing. This provides a verifiable safety check that conventional cotton simply does not have. Choosing GOTS-certified cotton is the only way to ensure the fabric touching your skin is free from this hidden agricultural burden.

Hemp vs Cotton: Which Plant Uses Less Water per T-Shirt?

Beyond chemical purity, the environmental impact of a fabric is a key part of its overall “cleanliness.” When comparing foundational fibers, the contrast in water consumption between hemp and cotton is stark. Conventional cotton is one of the most water-intensive crops in the world. Producing a single kilogram of cotton fabric, enough for just a few t-shirts, can require up to 20,000 liters of water, much of which comes from irrigation that depletes local rivers and aquifers.

Hemp, on the other hand, presents a dramatically more sustainable model. This robust plant thrives on natural rainfall in many climates, requiring minimal to no irrigation. It’s estimated that producing a kilogram of dry hemp fiber requires only 300-500 liters of water. This represents a water savings of over 95% compared to cotton. The illustration below highlights this profound difference between a rain-fed crop and an irrigation-dependent one.

From a textile toxicology perspective, this matters. Massive water usage for irrigation often goes hand-in-hand with increased fertilizer and pesticide runoff, contributing to environmental pollution that ultimately affects ecosystem and human health. According to a comparative analysis, hemp’s lower water needs and natural pest resistance make it an inherently cleaner agricultural product from the very start, reducing the chemical load on the environment long before it becomes a textile.

The Bamboo Fabric Lie: Why “Bamboo Viscose” Is Actually Toxic to Produce?

Bamboo is often marketed as a silky-soft, eco-friendly dream fabric. The plant itself grows rapidly with little need for pesticides or water. However, the transformation from a rigid bamboo stalk into a soft, drapable textile is a chemically brutal process that exposes a toxic reality. The vast majority of bamboo fabric on the market is not “bamboo” at all; it is bamboo viscose or rayon, a product of the viscose process.

This process involves dissolving bamboo pulp in a hazardous chemical solution. A key solvent used is carbon disulfide, a highly toxic and volatile chemical. Workers in viscose production facilities can suffer severe health consequences from exposure. In fact, Harvard T.H. Chan School of Public Health studies link chronic carbon disulfide exposure to neuropsychiatric symptoms, heart disease, and reproductive harm. Other chemicals like caustic soda and sulfuric acid are also integral to this process, posing significant risks to both workers and the environment when waste is improperly discharged.

While the final fabric is often stripped of these chemicals, the production method is antithetical to the principles of health and purity. For consumers seeking truly non-toxic and ethically made textiles, bamboo viscose is a clear contradiction. If you’re looking for safer alternatives, it’s critical to know what to look for:

- Be wary of products marked as ‘Viscose’ or ‘Rayon’—they have undergone this chemical-heavy processing.

- Look for the much rarer ‘Bamboo Linen’ or fabrics made with the ‘Lyocell’ process (like Tencel), which use a closed-loop system with a non-toxic solvent.

- Check for certifications like OEKO-TEX Standard 100, which tests the final product for harmful substances, or GOTS for a holistic view of the production chain.

- Prioritize inherently safe fibers like GOTS-certified organic cotton, hemp, and linen.

The “Break-In” Period That Makes Linen Softer Than Cotton Over Time

For those with sensitive skin, texture is as important as chemical purity. While new cotton can feel soft initially, linen possesses a unique quality: it improves with age. Brand-new linen can feel crisp, sometimes even stiff. This is due to the presence of pectin, a natural binding agent within the flax fibers. With each wash, this pectin gradually breaks down, allowing the long, smooth fibers to separate, relax, and soften.

This transformation is not a degradation of the material, but a refinement. Unlike cotton fibers, which are short and can break or pill over time, creating a rougher surface, linen fibers are long and exceptionally strong. The “break-in” period results in a fabric that becomes progressively smoother, more lustrous, and more comfortable against the skin. This microscopic evolution is what gives vintage linen its famously supple and luxurious feel.

This structural integrity also translates to incredible durability. While conventional cotton bedding or clothing may need replacement every two to three years due to wear and pilling, high-quality linen is an investment that can last for over a decade, and sometimes even for generations. This longevity makes its cost-per-wear significantly lower than cotton over time. For sensitive skin, linen offers the dual benefit of a naturally hypoallergenic, breathable fiber that only becomes more soothing with every use.

When to Buy Organic Linens to Get the Best White Sale Discounts?

Investing in high-quality, GOTS-certified organic linen is a significant step towards better skin health, but the premium price point can be a barrier. Strategic shopping, however, can make this investment much more accessible. Retailers operate on predictable seasonal cycles, and understanding them allows you to acquire superior linens at a fraction of their peak price. There are three key periods during the year to watch for the best discounts.

The most significant markdowns on linen often occur at the end of the summer season. As a fabric prized for its cooling properties, demand for linen peaks in the spring and summer. By late August and into September, retailers are eager to clear out this seasonal stock to make room for fall and winter collections. This is when you can find deep “Summer Clearance” discounts. The second-best time is during the traditional “White Sales” in January, a retail tradition dating back to the 19th century focused on bedding and bath linens. Finally, major sales events like Black Friday also offer opportunities, though the discounts may be slightly less substantial than end-of-season clearances. The table below outlines what to expect.

| Time Period | Discount Type | Expected Savings | Reason |

|---|---|---|---|

| Late August-September | Summer Clearance | 40-60% | Retailers clear seasonal linen stock |

| January | Traditional White Sales | 30-50% | Historic bedding sales tradition |

| Black Friday | Holiday Sales | 25-40% | General retail promotions |

The Hidden VOCs in Modern Furniture That Affect Your Sleep Quality

Your skin’s environment extends beyond the clothes you wear; it includes the air you breathe, especially during sleep. The average person spends around eight hours a night in the bedroom, a space that can be a concentrated source of airborne irritants. Modern furniture, particularly items made from particleboard, MDF, or treated with synthetic finishes, can release Volatile Organic Compounds (VOCs) into the air. These chemicals, including formaldehyde, can off-gas for years, contributing to poor indoor air quality.

This chemical off-gassing can be a trigger for respiratory irritation, headaches, and, for sensitive individuals, skin reactions. Your mattress, unless specifically chosen for its non-toxic materials, can be a primary culprit. Many conventional mattresses are made with polyurethane foams and synthetic adhesives that emit VOCs. This means that for a third of your life, your body is in close proximity to a low-level chemical source, which can disrupt sleep quality and place a constant burden on your body’s detoxification systems.

In this context, your choice of bedding becomes more than just a matter of comfort; it becomes a protective measure. As one Environmental Health Specialist noted in an Indoor Air Quality and Sleep Health Study:

GOTS-certified bedding acts as the final, pure barrier between your skin and potential off-gassing from your mattress – it’s the one part of the ‘sleep sandwich’ you can most easily control to reduce nightly chemical exposure.

– Environmental Health Specialist, Indoor Air Quality and Sleep Health Study

Using GOTS-certified organic cotton or linen sheets, pillowcases, and duvet covers ensures that the layer closest to your body is free from harmful chemicals. It creates a “clean zone” that minimizes your direct dermal and respiratory exposure, providing a sanctuary for rest and recovery.

Why Polyester Wicks Sweat but Smells Worse Than Wool?

The promise of synthetic athletic wear, particularly polyester, is its ability to wick sweat away from the skin, keeping you feeling dry. While it excels at moving moisture, it inadvertently creates the perfect environment for odor-causing bacteria. This phenomenon is a prime example of a fabric’s microbial hospitality. From a microscopic perspective, polyester fibers are smooth and non-absorbent. They push moisture to the surface, but also trap it in the weave, creating warm, humid pockets where bacteria can thrive.

Specifically, bacteria like *Micrococcus luteus* feast on the compounds in your sweat, producing the signature stale, funky odor associated with synthetic gym clothes. Because polyester is essentially a plastic, these bacteria can form biofilms on the fibers that are notoriously difficult to wash out. This is why a polyester shirt can start to smell again moments after you put it on, even when it’s clean.

Natural fibers like merino wool offer a starkly different environment. Wool fibers are complex, scaly structures that can absorb up to 30% of their weight in moisture vapor *before* feeling wet, drawing it away from the skin and into the core of the fiber. This keeps the surface of the skin drier. Furthermore, wool has inherent antimicrobial properties, thanks in part to the lanolin and complex fiber structure, which are inhospitable to bacteria. This is why wool garments can be worn multiple times without developing an odor. For sensitive skin prone to sweat-induced irritation or folliculitis, choosing wool or GOTS cotton over polyester can mean the difference between comfort and a bacterial bloom.

Your Action Plan: Auditing Your Athletic Wear for Odor Control

- Points of Contact: List all your high-sweat activities (running, gym, hiking) and the specific garments you currently wear for each.

- Collecte: Inventory your athletic drawer. Separate fabrics into piles: synthetic (polyester, nylon) and natural (cotton, wool). Note which ones develop “permanent stink.”

- Coherence: Confront your inventory with your goal of odor reduction. Recognize that the polyester pile is a breeding ground for bacteria, directly conflicting with your desire for freshness.

- Mémorabilité/émotion: Evaluate the “stink factor.” Does the persistent odor of your synthetic gear cause embarrassment or discomfort? Contrast this with the lasting freshness of a wool alternative.

- Plan d’intégration: Prioritize phasing out problematic polyester items. Start by replacing your most-used base layer with a merino wool or GOTS-certified cotton alternative and adopt a new washing routine using enzyme-based detergents for any remaining synthetics.

Key Takeaways

- “Natural” cotton is not inherently pure; only GOTS certification guarantees it is free from harmful pesticide residues from farm to fabric.

- Many “eco-friendly” alternatives like bamboo viscose are produced using a highly toxic chemical process. Prefer inherently pure fibers like linen, hemp, or certified organic cotton.

- The true value of a fabric lies in its long-term cost-per-wear and health benefits, not its initial ticket price. Durable, pure fabrics are an investment in well-being.

How to Build a Capsule Wardrobe That Lasts 5 Years Without Looking Dated?

The ultimate strategy for protecting sensitive skin and making sound economic choices is to synthesize these principles into a capsule wardrobe. A capsule wardrobe is a curated collection of a few essential, high-quality items that can be mixed and matched. By focusing on purity and durability, you create a collection that not only serves your health but also stands the test of time, both in style and substance.

The foundation of a long-lasting capsule wardrobe rests on timeless silhouettes and superior materials. Instead of chasing trends with disposable fast-fashion items made from irritating synthetics, invest in classic pieces made from GOTS-certified cotton, linen, hemp, or wool. These materials, as we’ve seen, are not only gentler on the skin but also far more durable. A GOTS-certified t-shirt, for example, is designed to last for years, not just a season.

This approach radically changes the economic equation of your wardrobe. While the initial cost of a GOTS-certified garment is higher, its longevity makes it far cheaper in the long run. A comprehensive economic analysis of sustainable wardrobe investment shows that one GOTS t-shirt lasting five years can cost up to 60% less per wear than the ten fast-fashion replacements you would have bought in the same period. Building a capsule wardrobe is therefore not about restriction; it’s about intentionality. It’s an investment in your personal health, your financial well-being, and the health of the planet, proving that the most sustainable and skin-friendly choice is also the most economical over time.

Start today by auditing a single category of your wardrobe, like t-shirts or sleepwear. Your journey toward a pure, comfortable, and lasting collection begins with that first intentional choice.

Frequently Asked Questions on Why Switching to GOTS-Certified Cotton Can Resolve Unexplained Skin Rashes?

Is European Flax certification equivalent to GOTS for linen?

European Flax certification ensures origin and quality but doesn’t cover the entire processing chain like GOTS does, making GOTS the more comprehensive standard for chemical-free processing.

Why is organic linen more expensive than organic cotton?

Linen requires more complex processing from flax plants, but its extreme durability (lasting 10+ years) makes the cost-per-use actually lower than cotton over time.

Should I wait for sales or buy organic linens at full price?

Calculate the cost-per-year: even at full price, quality certified linen lasting a decade often costs less annually than discounted conventional bedding replaced every 2-3 years.